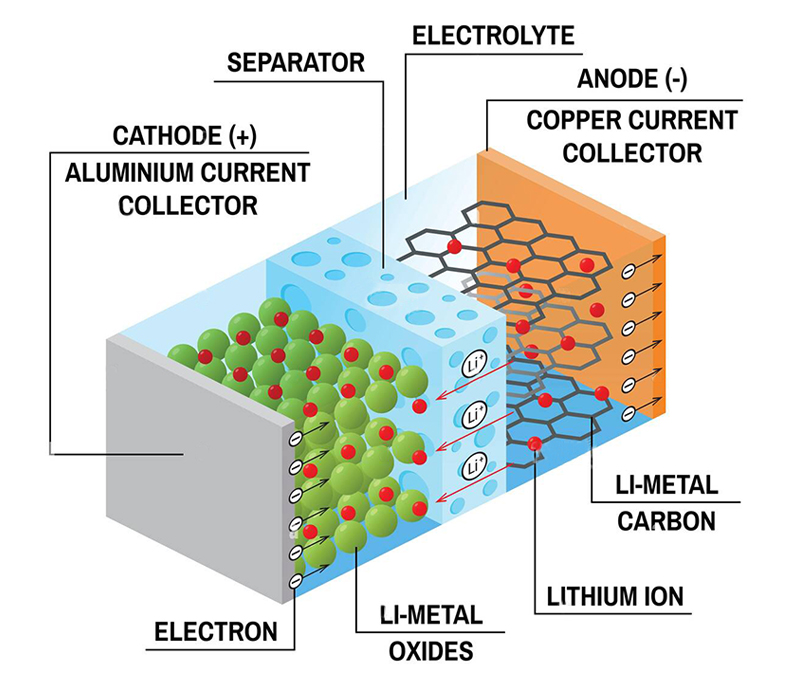

Dielectric Layer Coatings for Lithium-ion Battery Manufacturing

Ultrasonic coating systems are used for polyimide coatings to create insulating layers in applications requiring a chemically inert protective coating. Polyimide coatings can replace Kapton tape for difficult geometries and smaller areas (channels, holes), encapsulating materials and protecting Lithium and other hazardous materials from unwanted reactions or leaks. For batteries using radioactive or highly reactive elements, polyimides are used as flexible encapsulation materials with good structural integrity. Benefits of using ultrasonic spray for polyimide encapsulating layer coatings include:

Ultrasonic coating systems are used for polyimide coatings to create insulating layers in applications requiring a chemically inert protective coating. Polyimide coatings can replace Kapton tape for difficult geometries and smaller areas (channels, holes), encapsulating materials and protecting Lithium and other hazardous materials from unwanted reactions or leaks. For batteries using radioactive or highly reactive elements, polyimides are used as flexible encapsulation materials with good structural integrity. Benefits of using ultrasonic spray for polyimide encapsulating layer coatings include:

- Durable, mechanically stable layers

- Nozzles have no moving parts to wear out

- Desirable dielectric properties

- Extensive expertise with polyimide coatings

- Extensive experience coating microporous membranes

- Very uniform thin films with high repeatability

- High temperature resistant coatings perform in temperatures up to 400 degrees C

Visit https://www.sono-tek.com/ultrasonic-coating/ultrasonic-spray-benefits/ to learn more about how ultrasonic spray is an effective method for applying protective polyimide layers in automotive, medical or other industry applications.