Uniform Coatings of Thin Film Solar Cell Active Layers

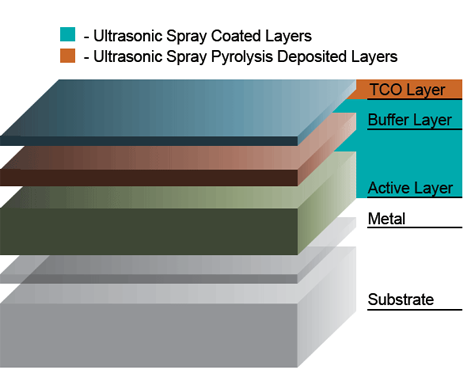

Ultrasonic spray technology has been proven successful for depositing thin film solar cell coatings of anti-reflection layers, TCO coatings, Buffer layer coatings, PEDOT, and active layers in thin film and perovskite solar cell manufacturing. OPV, CIGs, CdTE, CzTs, Perovskite, and DSC are some of the solutions and suspensions that can be deposited using ultrasonic wet process spray technology in manufacturing thin film solar cells. At a fraction of the cost of CVD and sputtering equipment, ultrasonic atomizing spray nozzle systems reduce cost per watt for manufacturing thin film solar cells, while still providing high cell efficiencies.

Sono-Tek ultrasonic spray coaters are a fraction of the cost of sputtering and CVD equipment, with many systems used in R&D for perovskite spray coatings and other thin film solar manufacturing applications. Ultrasonic spray technology continually gains recognition as a viable method for upscaling to larger sizes and higher volume thin film solar manufacturing. Sono-Tek plays an important role in transferring proven R&D processes into high volume manufacturing operations for many different layers and types of solar cell technologies and thin film solar cell coatings.

Active Layers

Active Layers

- OPV

- Perovskite

- CIGS

- CdTe

- CZTS

- DSC

Quantum Dots

Nano-crystal semiconducting dots contain Zn, Pb, Cd, Se. Advantages of ultrasonic spray include drastic reduction in cost of capital equipment for initial investment, deagglomeration of particles held in suspension during spray process, proven scalable production solutions for migration from R&D to production volume with inline processing, and transfer efficiencies as high as 95%, reducing consumption of expensive raw materials.

Buffer and/or Organic Layers

Typical materials Sono-Tek coating equipment is used for:

- CdS – a common buffer layer used in CIGS, CDTe cells

- Organic Cell Polymers – PEDOT, PCBM, P3HT, P3HD

TCO Layers

TCO (Transparent Conductive Oxide) consists of metals dissolved in solution having high conductive and transparent properties. Sometimes applied at high temperatures in pyrolysis reaction and often require high temperature annealing at roughly 500 degrees C. TCO layers requiring high temperature are typically coated using a spray pyrolysis technique.

Sono-Tek spray coating equipment is used for:

- ITO

- ZnO (Doped with Ga, Al, In)

- CdO

- SnO2

CNTs/Silver Nanowires (AGNW)/Graphene

CNTs have potential to replace ITO in TCO layers due to abundant raw material, excellent stiction and extremely high conductivity. Sono-Tek ultrasonic nozzle provide great benefit in depositing these nanomaterials due to deagglomeration of particles during the atomization process. Ultrasonic vibrations keep particle homogeneously distributed in solution.

Anti-Reflection (AR) Coatings

AR Coatings increase cell efficiencies by 3-4%. Sono-Tek provides coating systems for depositing:

- SiO2

- TiO2

- Other formulations