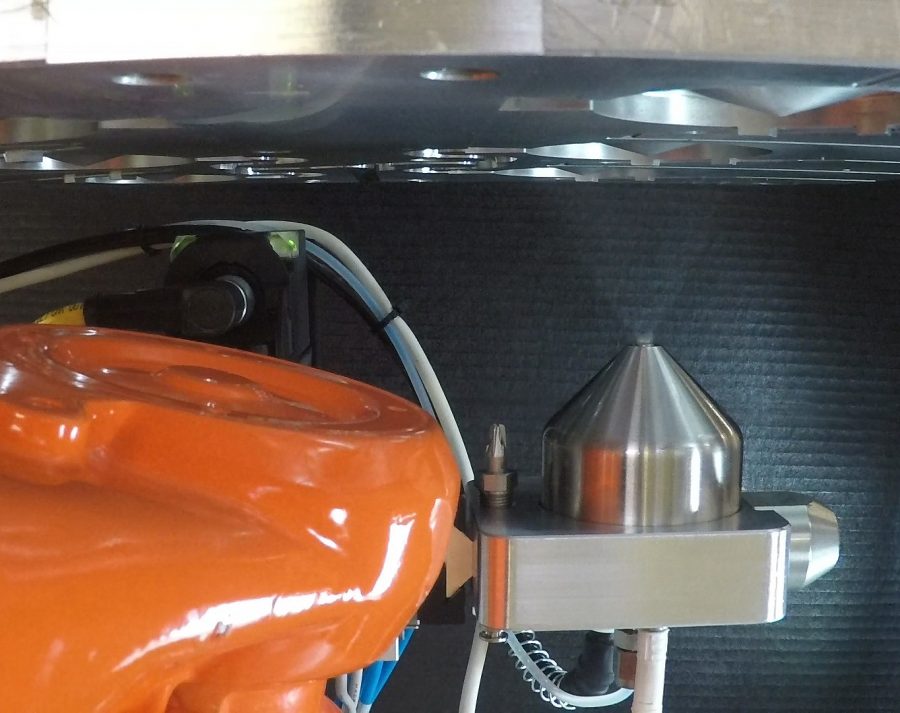

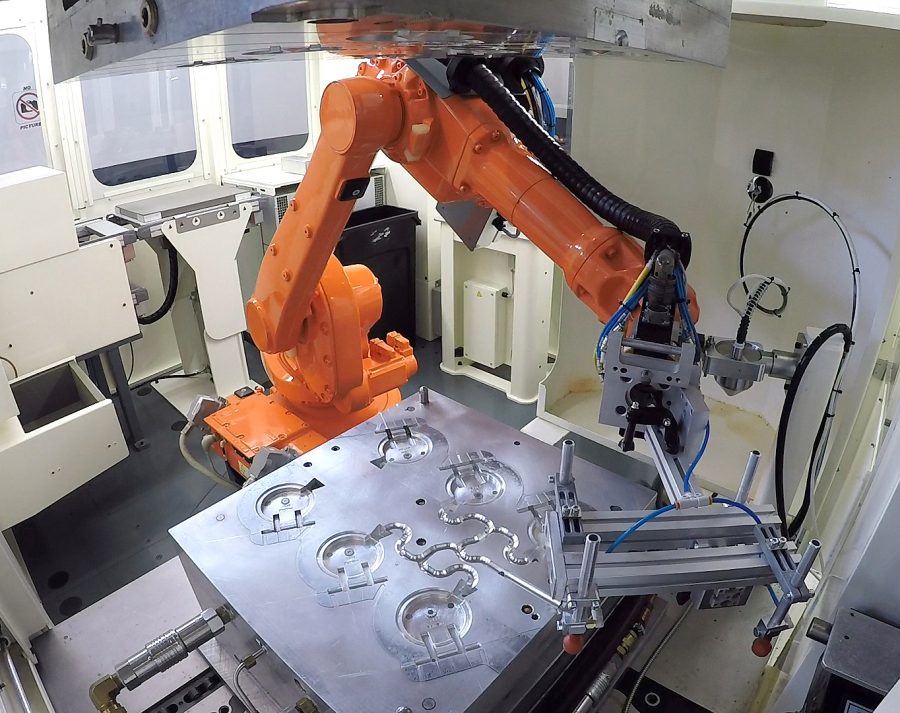

Ultrasonic nozzles used in injection mold release coating applications typically integrate onto robotic arm platforms for fully automated processes. These critical coatings enable the cured part to be easily separated from the mold during production, and protect the mold during heavy injection cycling.

Release agent coatings are usually applied before a set number of mold injection cycles, depending upon process requirements. The process shown below is coated at the beginning of every 10th injection cycle.

Optimal ultrasonic spray deposition of injection mold release coating agents can:

- Enhance productivity.

- Decrease cycle times.

- Improve product surface quality.

- Reduce scrap rate.

- Provide minimal build up on molds and tooling.

- Provide a reduction in (minimal) pin holing.

- Enhance flow characteristics of mold release, due to very small drop size.

- Increase mold service life.

- Influence maintenance cycles (reduce the frequency of maintenance cycles).

- Reduce defects.

- Reduce consumption of mold release agent by 50% – 75%.

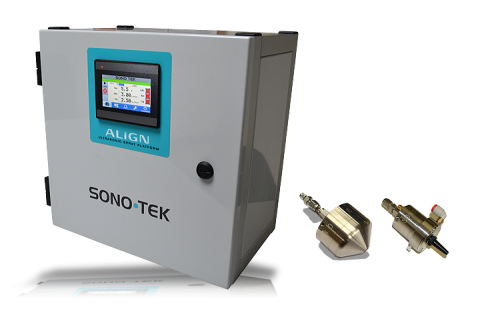

The system easily integrates with mold injection machinery, for challenging release applications. It is ideal for intricate geometry, tightly spaced mold designs. Different spray shape designs available to accommodate products of varying size and shape (AccuMist and Vortex nozzles are commonly used in these applications).

“For over 4 decades, MPI has been leading technical innovation in the casting and wax injection industry. The unique thin film mold release coverage capability provided by Sono-Tek ultrasonic atomization machinery allows for significant defect reductions that would normally be caused due to excess mold release agent applied with conventional spray methods. MPI considers it critical to provide our customers with the latest and most advanced technologies to meet their needs. The additional of Sono-Tek ultrasonic spray was an easy choice, keeping with this philosophy.”

MPI Systems