Ultrasonic spray of molten metals for producing solder powder

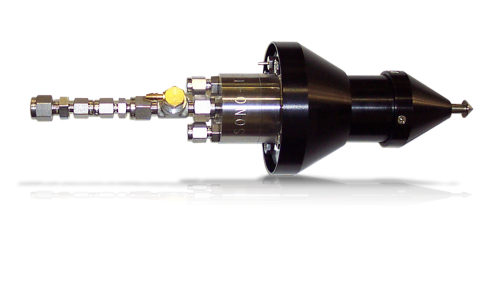

The MoltenMist is a unique ultrasonic nozzle designed to atomize molten metals and other melts, such as solder, for production environments in solder paste manufacturing.

In applications that require a very precise diameter size, such as solder powder, commonly used to manufacture solder paste, ultrasonic nozzles are a perfect fit.

Ultrasonic nozzles have long been known to be an ideal tool for atomizing molten metals and melts, such as solder. However, temperature constraints and wear on a nozzle’s atomizing surface have made them impractical for production environments. The MoltenMist line of ultrasonic nozzles overcomes these problems by employing dual air/liquid cooling, and a simple, replaceable atomizing surface design. This proprietary cooling method keeps the nozzle’s heat sensitive piezoelectric transducers well within safe temperature limits, even when atomizing molten liquids.

For corrosive liquids, it is a simple procedure to install a new titanium atomizing tip when corrosion starts to affect nozzle performance.

By placing a liquid feed tube in close proximity to the atomizing surface, and flowing the molten solutions onto it, flow rates are capable in excess of 80 ml/min in air and 100 ml/min under vacuum or in inert atmospheres (With SN63PB37 molten solder, 680 g/min in air, 850 g/min under vacuum).