Ultrasonic fluxing equipment for OEM wave solder fluxing partners

For over 20 years Sono-Tek has been supplying our ultrasonic fluxing nozzles to our OEM wave solder fluxing partners. When purchasing a new wave or selective solder machine current Sono-Tek customers and those new to Sono-Tek, are able to take advantage of our unique ultrasonic technology. Choosing the ultrasonic spray fluxing option when specifying in a solder machine, adds a higher level of quality, flexibility, control, and reliability to your through hole manufacturing process.

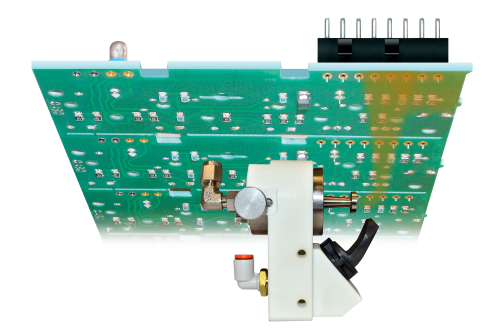

Sono-Tek works with the premier wave and selective solder machine manufacturing companies to engineer our ultrasonic fluxing technology into their spray fluxing platforms. The result is a fully integrated enhancement that customers are able to use to improve their soldering process.

The Sono-Tek ultrasonic upgrade for OEM wave solder fluxing machines features:

- Up to 70% reduction in flux consumption and VOC’s when compared to alternative spray fluxing technologies.

- Compatible with ALL fluxes.

- Reduced wasteful overspray and atmospheric contamination.

- Lower maintenance when compared to all other spray fluxers.

- Self-cleaning ultrasonic nozzle will not clog and has no moving parts.

- Small droplets result in excellent through hole penetration for maximum top-side fill.

The Sono-Tek ultrasonic upgrade for selective solder machines features:

- Compatible with ALL fluxes without clogging.

- Increase throughput compared to slow jetting technology.

- Vastly reduced overspray and satellite flux droplets.

- Lower maintenance.

- Self-cleaning ultrasonic nozzle will not clog and has no moving parts.

- Excellent through hole penetration for maximum top-side fill.

- Highly repeatable and accurate spray.