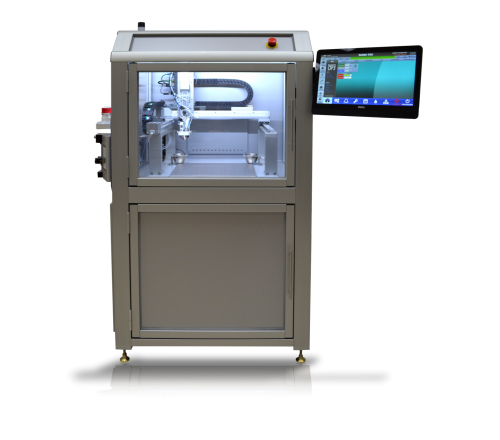

A standalone programmable three-axis robot ultrasonic full coating solution. This system employs robust ball-screw slides driven by brushless DC servo motors. Spray pattern widths can be easily shaped depending on which nozzle is used. Custom Windows-based software makes it easy to program and store a variety of spray patterns for automated processes.

Visit How Ultrasonic Nozzles Work to learn more about the unique capabilities of ultrasonic spray.

Alternative Energy & Nanomaterials

Glass & Industrial

Semiconductor

Basic Specifications

| Enclosure Dimensions: 1021mm W x 1693mm H x 997mm D (40.2”W x 66.7”H x 39.2”D) |

| Range of Motion*: 420 mm x 480 mm x 85 mm (16.5” x 18.9” x 3.3”) *Note: Work area may be reduced depending upon system configuration |

| Control: Windows-based programming software and on-screen teach device |

| Power Requirements: 100-240 VAC, 50/60 Hz, 4.5A max base system, 17A max with standard heat plate |

| Air: 551.6 kPa (80 PSI) dry unlubricated air |

| Motors: Brushless DC servo |

| Certification: CE |

| Ultrasonic Nozzle Designs: AccuMist, Impact, Vortex, MicroMist, or Propel |

System Options

| Common Options: Wire/rod coater, Ultrastatic ESC, glovebox enclosure with or without filtration, standard floor standing enclosure. |

| Liquid Delivery: Common Liquid Delivery: Syringe pump (standard, Sonic or stirring), MicroFlow, SonoFlow Fusion Heat and/or Vacuum Plate: 150 degrees C heat and or vac Head configuration: Up to two heads (Ultrasonic or Vector) |

| : *Additional custom options may be available depending upon application requirements |