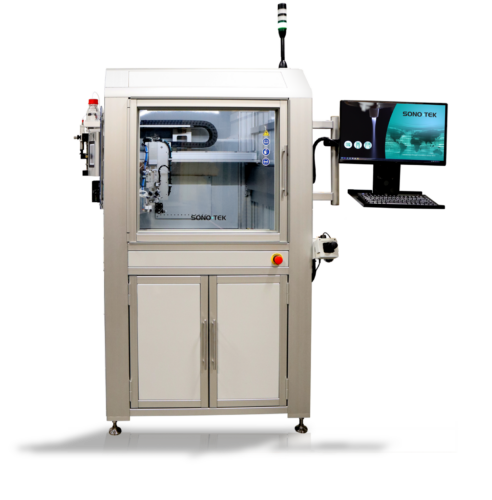

A standalone programmable three-axis robot ultrasonic full coating solution. Single or multiple Sono-Tek ultrasonic nozzles can be integrated. A variety of system options are available for integration. Windows®-based software makes it easy to program and store spray patterns for automated processes. NovoCoat is available in several gantry sizes to suit small to large substrates

Visit How Ultrasonic Nozzles Work to learn more about the unique capabilities of ultrasonic spray.

Alternative Energy & Nanomaterials

Glass & Industrial

Semiconductor

Basic Specifications

| Spray Area: 600x600mm, 800x800mm or 1000x1000mm |

| Motor: Brushless DC servo |

| Resolution: 0.02 mm (0.0008 in) |

| Power Requirements*: 208-240VAC 50/60Hz 1-phase *Without heat plate |

| Ultrasonic Nozzle Designs: AccuMist, Impact, Vortex, MicroMist, or Propel |

System Options

| COMMON OPTIONS: Wire/rod coater, Ultrastatic ESC, glovebox enclosure with or without filtration, standard floor standing enclosure. |

| LIQUID DELIVERY: Common Liquid Delivery: Syringe pump (standard, Sonic or stirring), MicroFlow, SonoFlow Fusion Heat and/or Vacuum Plate: 150 degrees C heat and or vac Head configuration: Up to two heads (Ultrasonic or Vector) |

| : *Additional custom options may be available depending upon application requirements |