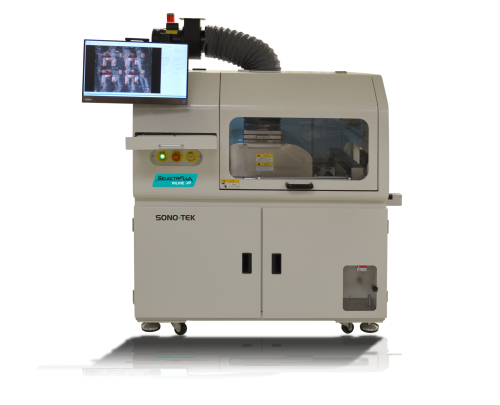

A fully automated multi-axis ultrasonic wave solder spray fluxing system with precision selective area fluxing capability. Advanced point programming capable; just import an image of the PCB and highlight the desired areas to be fluxed. Ideal for pallets and PCB’s with unnecessary areas to be fluxed. Has been proven to reduce flux consumption by up to 93%. Designed for medium to high mix lines, the system has a barcode option allowing the capability to change desired flux areas on the fly. The system is available in a standalone format for easy installation in front of any wave solder machine. Due to the advanced spray precision of the SelectaFlux X2, maintenance is reduced by 95% compared to conventional pressure spray fluxers. All SonoFlux systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance.