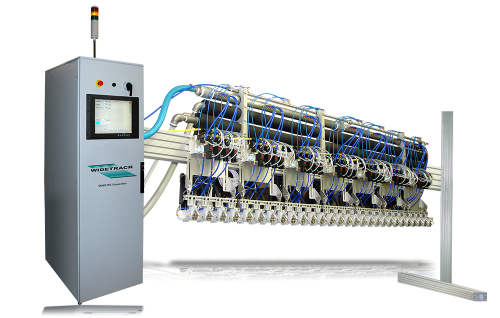

A high volume production coating system for wide area coatings such as glass and textiles manufacturing. Up to 28 Impact air shaping systems are mounted on a single bridge assembly, with the ability to customize widths. The system features: uniform, repeatable thin film coatings across wide widths, customized widths available and proven performance for 24/7 high volume production operations.

Visit How Ultrasonic Nozzles Work to learn more about the unique capabilities of ultrasonic spray.

Single Bridge Impact Nozzles20-nozzle Impact bridge assemblyWideTrack Wide Area Glass Coating SystemsUltrasonic Coating Systems for TextilesWater & Oil Repellent Coating Systems

Glass & Industrial

Basic Specifications

| Spray Width: custom widths up to 3.3m (130”) configuration up to 28 impact spray assemblies |

| Control: Windows-based industrial embedded controller (modern PLC) with 19” touch screen HMI, NEMA 12 cabinet cooled by integrated AC |

| Power Requirements: 220 VAC, 25-50A (depending on configuration) L,L, N, G 50/60 Hz (base model) |

| Air: 621-1034 kPa (90-150 PSI) @ 3000LPM (110 CFM) max, 500LPM (~20CFM) typical. Clean, dry and oil-free |

| Certification: CE |

| Ultrasonic Nozzle Designs: Impact |

System Options

| : Up to 28 spray assemblies, insulated liquid lines to maintain liquid temperatures when required |