Equipment Solutions

Equipment solutions from R&D through high volume production. Choose a product to learn more.

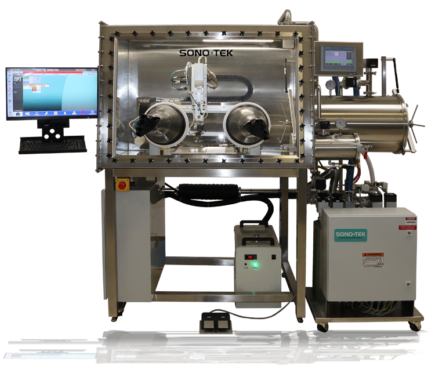

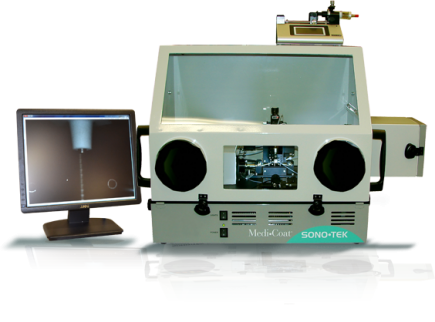

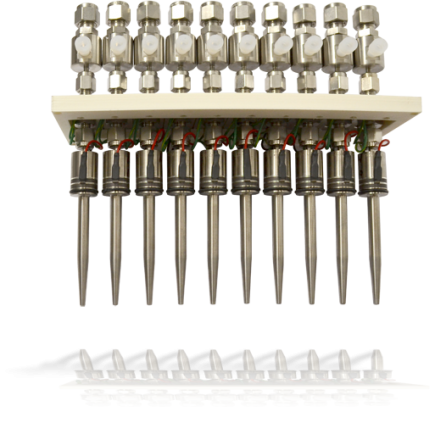

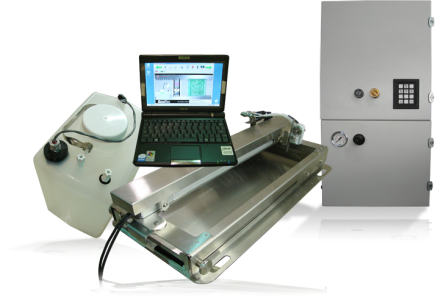

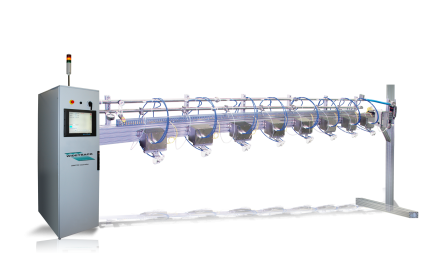

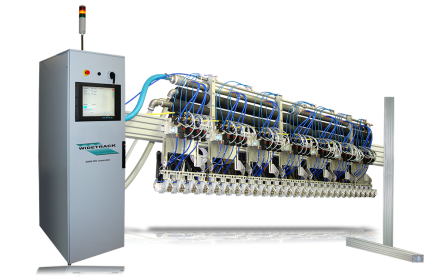

All of Sono-Tek’s ultrasonic coating systems integrate Sono-Tek ultrasonic nozzles, liquid delivery, and full system controls. Machines range from R&D tabletop systems, standalone fully enclosed programmable systems, and wide area continuous production inline systems.

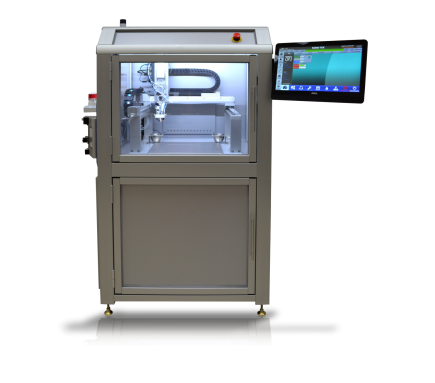

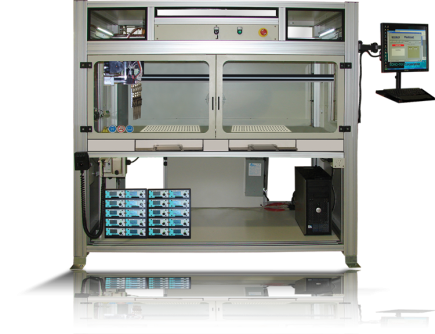

ExactaCoat

Automated, programmable benchtop coating system with coordinated XYZ motion control using Windows-based software and user-friendly teach pendant with trackball. Versatile R&D to mid-volume production thin film coatings.

Visit How Ultrasonic Nozzles Work to learn more about the unique capabilities of ultrasonic spray.

Click on the links below to learn how this system is commonly used in the following industry applications:

Alternative Energy & Nanomaterials

Glass & Industrial

Medical

Basic Specifications

| Dimensions: 944 mm W x 831 mm H x 794 mm D (37.2” W x 31.2” H x 32.7” D) |

| Work Area*: 400 x 400 x 100mm (15.75” x 15.75” x 3.94”) |

| Control: Windows-based (PC included) |

| Power Requirements: 120V, 220V, +/-10%, 50-60Hz |

| Air: 551.6 kPa (80 PSI) dry unlubricated air |

| Motors: Brushless DC servo |

| Certification: CE |

| Ultrasonic Nozzle Designs: AccuMist, Impact, Vortex, MicroMist, or Propel |

System Options

| Heat and/or Vacuum Plate: 150, 250C heat/vac or 500C heat |

| Head configuration: up to two heads (Ultrasonic or Vector) |

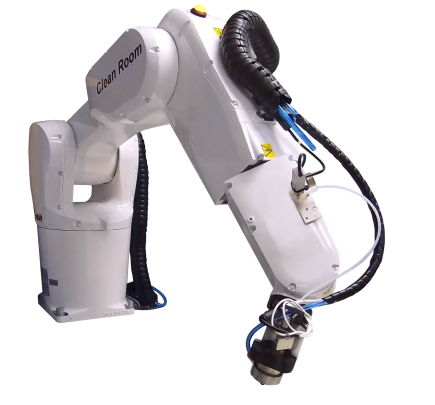

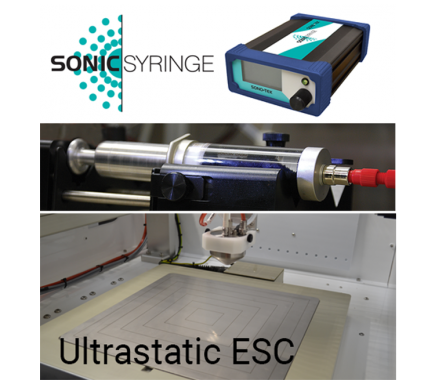

| Common Options: Wire/rod coater, Ultrastatic ESC, Nozzle rotate and or tilt, 1 or 2 drawer load system, N2 Rich Environment, LEL Sensors, cleanroom upgrade, aggressive material upgrade |

| Liquid Delivery: Common Liquid Delivery: Syringe pump (standard, Sonic or stirring), gantry mounted syringe pump, MicroFlow, SonoFlow Fusion, HyperFlow catalyst pump |

| *Additional custom options may be available depending upon application requirements |