Performance and Cost Benefits of Sprayed EMI Shielding Expected to Drive Market Growth

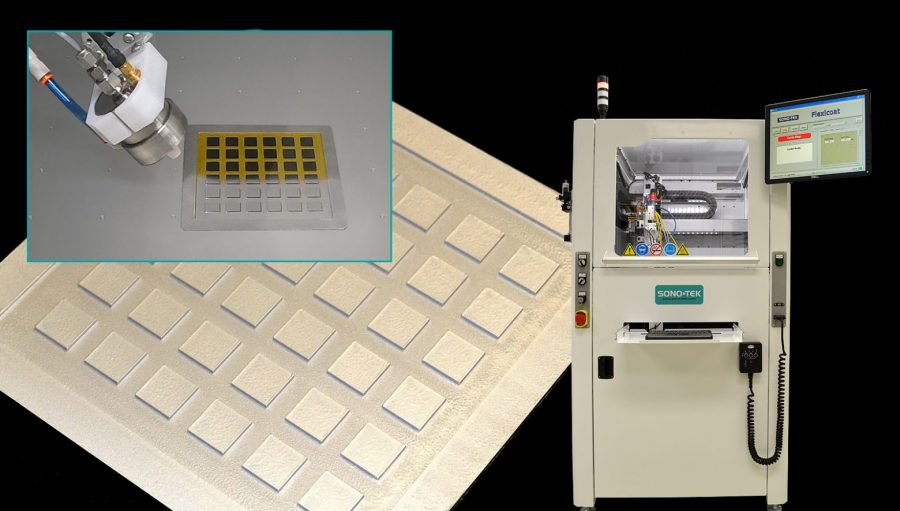

MILTON, N.Y., January 7, 2020 — Sono-Tek Corporation (OTCQX: SOTK), the leading developer and manufacturer of ultrasonic coating systems, today announced a new ultrasonic coating system, the FlexiCoat EMI, specifically designed for conformal spraying of EMI (Electromagnetic Interference) shielding material onto semiconductor packages.

FlexiCoat EMI is an automated XYZ coating system specifically engineered and proven to spray copper and silver-filled shielding materials with precise control of coating characteristics and little overspray. Sono-Tek developed a special ultrasonic nozzle configuration for these EMI applications that provides a more targeted spray area that drastically reduces overspray when compared with all other spray types. Sono-Tek’s ultrasonic nozzles are well known for their low/no maintenance, non-clogging, high uniformity, and highly repeatable performance. This new nozzle design is fully integrated into the FlexiCoat EMI system, along with an array of other application-driven features to make the system a full coating solution for EMI shielding coatings. This includes a proprietary ink mixing system to ensure that the ink maintains its stability over time and that is compatible with ink formulations from major ink providers.

The FlexiCoat EMI is an innovative solution to the dispensing of shielding materials for semiconductor packages and a new direction for the market that is in the early stages of transitioning away from sputtering. Ultrasonic coating is a more cost-effective, faster and simpler alternative to expensive sputtering-based coating equipment and conventional techniques, such as shield cans and SMT clips, that are inadequate for newer smaller devices, including some of the small components that go into phones and other mobile devices, that need to be protected against EMI (ElectroMagnetic Interference) by shielding them with a coating of conductive material. This new and growing market focused on EMI shielding protection properties for smaller devices and components is a natural fit for Sono-Tek, whose ultrasonic coating solutions provide a more uniform precision coating suitable for fuel cells, advanced solar cells, medical devices, electronics and semiconductors, and many other high technology surface applications.

“Sono-Tek’s entry into this new semiconductor application was a logical outgrowth of our semiconductor coating expertise in other applications. Our equipment is quickly proving to be an excellent fit for companies looking for an effective, low-cost alternative to sputtering for deposition of new copper and silver-filled epoxy materials on the market. We expect that the market will begin to grow at an increasing rate as the performance and cost benefits of sprayed EMI shielding become better known,” said Bennett Bruntil, Vice President of Sales & Marketing of Sono-Tek.

About Sono-Tek

Sono-Tek Corporation is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or provide additive or enhanced surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

The Company’s solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Sono-Tek’s growth strategy is focused on leveraging its innovative technologies, proprietary know-how, unique talent and experience, and global reach to further develop thin film coating technologies that enable better outcomes for its customers’ products and processes. For further information, visit www.sono-tek.com.

Safe Harbor Statement

This news release contains forward looking statements regarding future events and the future performance of Sono-Tek Corporation that involve risks and uncertainties that could cause actual results to differ materially. These factors include, among other considerations, general economic and business conditions; political, regulatory, tax, competitive and technological developments affecting our operations or the demand for our products, including the imposition of tariffs; timely development and market acceptance of new products and continued customer validation of our coating technologies; adequacy of financing; capacity additions, the ability to enforce patents; maintenance of operating leverage; maintenance of increased order backlog; consummation of order proposals; completion of large orders on schedule and on budget; continued sales growth in the medical and alternative energy markets; successful transition from primarily selling ultrasonic nozzles and components to a more complex business providing complete machine solutions and higher value subsystems; and realization of quarterly and annual revenues within the forecasted range. We refer you to documents that the company files with the Securities and Exchange Commission, which includes Form 10-K and Form 10-Qs containing additional important information.

Contact:

Stephen Bagley, CFO

Sono-Tek Corporation

info@sono-tek.com

845-795-2020

Investor Relations:

Stephanie Prince

PCG Advisory

(646) 762-4518

sprince@pcgadvisory.com