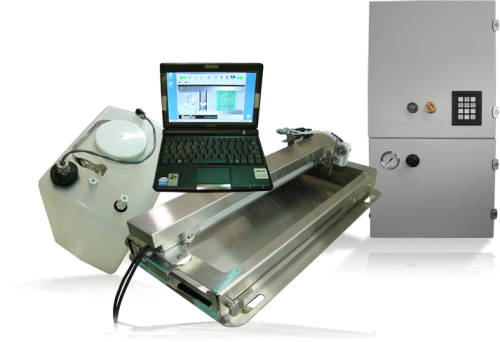

A fully automated reciprocating ultrasonic wave solder spray fluxing system with selective area fluxing capability, available dual flux, and InSight auto board recognition functionality. Easy integration and operation with all wave solder machines and designed for medium to high mix lines. All SonoFlux systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance with up to 80% reduction in flux consumption.

Optional InSight automated board recognition is available for fully automated recipe change. Boards are recognized using either an imaging camera or bar code scanner system. InSight ‘s intuitive software allows you to easily associate existing recipes with each board’s image or bar code. Once assigned, associated recipes can be automatically queued with the image recognition or bar code reader, without operator intervention. To learn more about InSight’s capabilities, click here: https://www.sono-tek.com/wp-content/uploads/2019/02/InSight-Web-Product-Details.pdf

Printed Circuit Boards

Basic Specifications

| Reciprocator Dimensions: 46 cm (18”) configuration: 84 cm x 41 cm (33” x 16”) or 61 cm (24”) configuration: 104 cm x 41 cm (41” x 16”) |

| PCB Width Range: 50-457mm (2–18 inches) or 50-610mm (2-24 inches) |

| Control: PC-based |

| Flux delivery: High precision gear pump |

| Power Requirements: 110/120 VAC, 50/60 Hz or 220/240 VAC, 50/60 Hz, Single phase, 900 VA max |

| Air: 345-689 kPa (50-100 PSI) @ 170 LPM (6 CFM) |

| Motors: Closed loop drive with ball screw |

| Certification: CE |

| Ultrasonic Nozzle Designs: Impact flux head |

System Options

| Options: External enclosure and conveyor, auto dual flux, InSight board recognition system, conveyor speed sensing, bar code reader, aggressive flux configuration |